Pneumatic

pumps

Air-actuated double diaphragm pumps have long been recognized as the most flexible pumps in the industry for handling difficult liquids at relatively low pressures and flows. The range of applications is practically unlimited, almost any type of liquid can be pumped, from highly corrosive acids, high viscosity paints and adhesives, to food and beverage products

Pneumatic pump Metalic Line

Aluminum · AISI 316 stainless steel

Compact and portable pumps, suitable for dry running without damage to the pump, and with suction capacities up to 6 m. Strong chemical resistance to acids, solvents, hydrocarbons or abrasive liquids, and suitable for high temperatures

Features

-

Low fluid handling

-

Materials: Aluminum or AISI 316 stainless steel

-

Flow rates from 8 to 1,000 L/min

-

Connections from ¼” to 3”

Applications

-

Difficult liquids at relatively low pressures and flows

-

Ideal for abrasive, dirty, viscous fluids or with solid parts

-

High viscosity paints and adhesives

-

Petrochemical industry, water treatment or automotive industry

Pneumatic pump Plastic Line

Polypropylene · PVDF · POMc

Pneumatic system entirely made of robust and corrosion-resistant plastic, with high chemical compatibility. General use, with different types of membrane materials depending on the fluid to be pumped

Features

-

Pneumatic exchanger easily accessible from the outside for quick inspection

-

Materials: Polypropylene, PVDF or POMc

-

P ossibility of external control of the pump for precision applications such as dosing

-

Flow rates from 8 to 1,000 L/min

-

Connections from ¼” to 3”

Applications

-

For a wide range of solvents and hydrocarbons

-

Highly corrosive acids

-

Abrasive liquids

-

Mining, pharmaceutical and naval sectors

-

C eramics, textiles and tannery sectors

Pneumatic pump Sanitary Line

AISI-316 electro polished Stainless steel

Pneumatic pumps specifically designed to meet the sanitary requirements of the food and beverage industry, with total visual inspection, high flow check valves, CIP ready and non-lubricated air valve

Features

-

Optimum resistance to corrosion and abrasion.

-

Equipped with high efficiency non-lubricated oil-free air valve, ensuring the most sanitary environment

-

Tri-clamp sanitary connection as standard

-

Viscosities up to 150,000 CP

Applications

-

Food, beverage, pharmaceutical and cosmetic products

-

Thick and viscous products as tomato paste and peanut butter

-

Shear sensitive products such as lotions and icings

-

Delicate products such as cottage cheese and yogurts

-

Meat, poultry and seafood industries

-

Handling large solids at high flow rates

Working principle

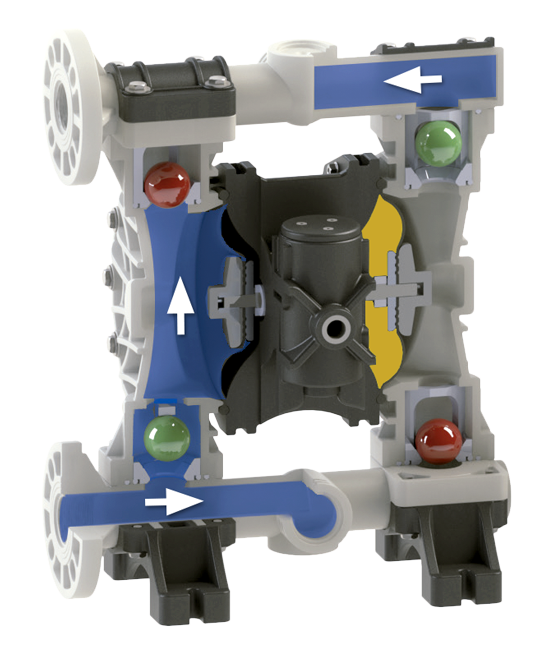

1 Suction cycle

Compressed air fills the right internal chamber, thanks to the movement of the opposite diaphragm it creates, by lifting the ball of the lower valve, the suction of the incoming liquid. At the same time, the left chamber is in the "discharge" cycle

Fluid

Air

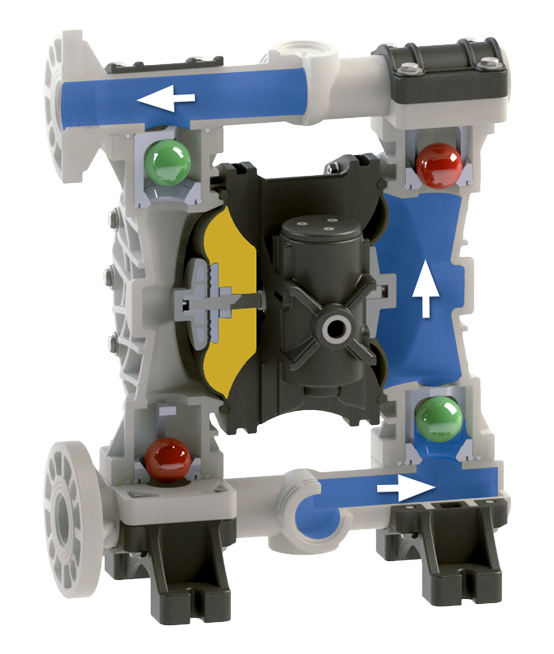

2

Discharge cycle

Compressed air fills the left inner chamber, in the opposite chamber, lifting the ball of the upper valve, discharges the fluid. At the same time, the left chamber is in the “suction” cycle