A Solutions

company

We offer planned maintenance and corrective maintenance services, which guarantee that your pumping installation is always in optimal condition. We also have an equipment repair service, where we use only original spare parts, which minimizes the downtime of your installation. A large stock in our warehouse in A Coruña, delivery times generally shorter than those of our competitors and agile delivery logistics allow us to maximize availability

Installation, commisioning &

Turnkey solutions

Our technicians have years of combined experience and an understanding of multiple systems, ensuring your complete process is working correctly

Systems and pumps installations

Filtration sytems

Chemical product dosing systems

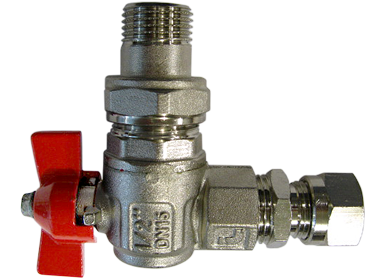

Pipework and valves modification and installations

Turnkey purification water treatment plants

Water disinfection systems installations

Pressure vessels and tanks installations

Compressors and air pressure equipment systems

Automation and control panel installations

Industrial water treatment systems

Fault finding to identify the cause of the failure

Flow measurement equipment installations

Industrial process systems installations

Fire protection systems installations

Technical support

+45 years experience allow us to provide added value to our clients

We propose reliable solutions in water purification, water treatment and fluid control

Selecting the most suitable pump for your fluid transport application

Extensive collaboration with

engineering companies

in their technical projects

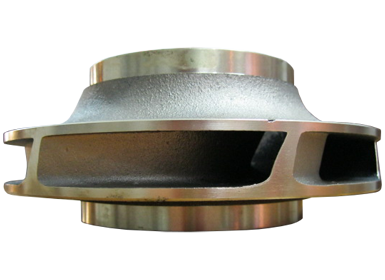

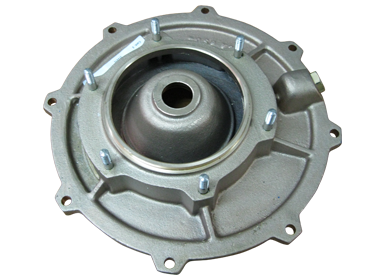

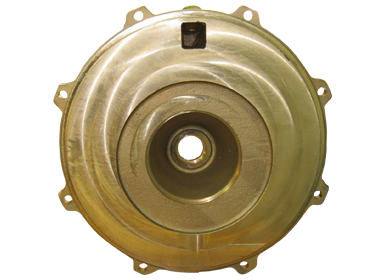

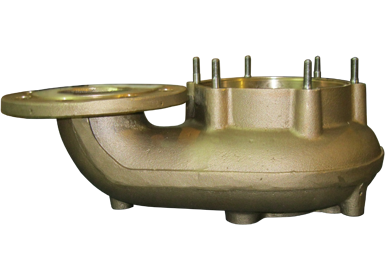

Original spare parts

Wide stock of original replacement parts of the brands for which we are an authorized agent at your disposal. Think about how genuine parts can benefit your business

Guarantee

Original spare parts allow us to continue offering the manufacturer's warranty for the equipment.

Remember that the use of generic or modified spare parts may void the equipment warranty

Functionality

Manufacturers adjust their equipment to allow their customers to maximize their systems performance and production by ensuring updating on their original spare parts

Compatibility

Although they may look and function the same, generic parts are not necessarily the same composition as the specified originals. Parts that are not manufactured to the same tolerances, holes that are not aligned causing a poor fit during installation, inferior welding which can cause cracks and deteriorate the quality of the entire assembly. Original spare parts have an important attribute compared to generic ones: compatibility

Availability

We understand that downtime is extremely expensive, which is why we stock the most common and essential components for the operation of your equipment.

For the other components, the usual availability is about 2 weeks - ask us about your case

Durability

The use of original spare parts is essential to prolong equipment useful life. Genuine parts are designed to last by meeting factory parameters, thus increasing the intervals between maintenance

Quality

Nobody like the manufacturer knows their equipment. Original spare parts are specifically designed for them, with materials and manufacturing processes that require their own quality controls

After sales assistance

We seek the comfort and maximum satisfaction of our customers after they have made the purchase

Maintaining contact with our customers allows us to identify areas for improvement and in the long run to improve the product

Technical team at the customer's disposal with the necessary know-how to solve any problem that may emerge in the use, configuration or installation of the product

Products guarantee against manufacturing faults and exchange or return management service with surcharge

Facilities maintenance

Preventive maintenance service, corrective maintenance service and 24-hour emergency care service

Preventive maintenance or conservation plans include periodic inspections of your machinery, in order to check their status and avoid future breakdowns

Carrying out a good maintenance of the machinery makes your installation more profitable in the long term, avoids paralyzing the production process due to breakdowns and allows to extend the useful life of the equipment, which is a great competitive advantage

Corrective maintenance is responsible for repairing or making an improvement in the machinery in the event of an emergency. Our maintenance contracts include these types of actions, which are carried out with the prior approval of the budget

A 24-hour service is available to the customer to attend to emergencies or breakdowns caused by other than maintenance defects

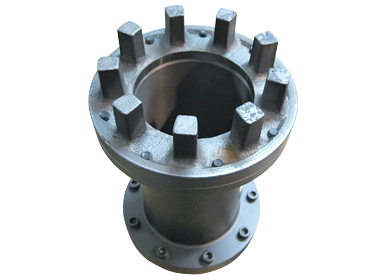

Repair service

Identifying the root cause of the equipment failure is key to ensure we can recommend the most effective option of repair or part replacement, resulting in removing persistent system failures.

Our team are experienced at carrying out repairs, from simple pump seal replacement to complete sewage treatment plant reconditioning. Our workshop repair service is specialized in the brands we represent.

Warranty

12 months

warranty offered by the manufacturers against manufacturer faults

15 days

products return service, as long as they are in perfect conditions with surcharge

Homologation

products approved by the most prestigious classification societies

Warehouse

deposit service at our facilities for a limited time